Stradale Tipo 33

The Stradale Tipo 33 project started in 2017 when we were approached by an Alfa Classic parts supplier to see if we could make their GRP Stradale bodywork fit a Vauxhall VX220 chassis, of which we have extensive knowledge.

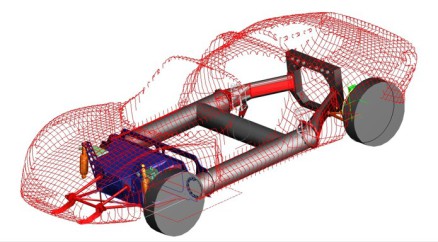

After making a few design changes to the VX220 components we decided that the correct approach was to design a bespoke chassis that was faithful to the original.

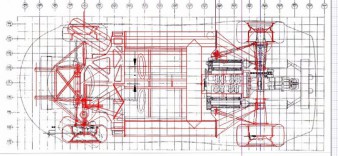

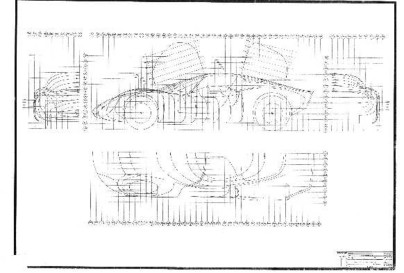

The starting point for the recreation of the chassis, was one small drawing found in the Alfa Romeo Tipo 33 Development and Racing History book.

Crucially this contained datums, which allowed the chassis to be redrawn in CAD to a high degree of accuracy (1mm in 2metres)

Along with a vast collection of images the missing details of the chassis were pieced together over a two year period.

We now had an accurate CAD drawing of the complete chassis, subframes and suspension along with their numerous mounting points.

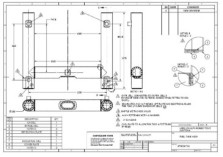

From this the time consuming process of designing the complex jigs could begin. In total some 20 jigs are needed to produce the complex chassis design, comprising centre section, front subframe, rear chassis legs, rear subframe and front and rear clamshell mounts.

These allow us to produce components that are interchangeable with each other if spare components are ever required.

The centre section is constructed from 200mm x 2mm wall steel tube, which is rolled from flat sheet to our specification. The original road cars also used steel for this section, only the race cars used magnesium.

All other parts are produced from laser cut mild steel that our MIG or TIG welded together on our Celette main chassis jig. There was a decision made at the start of the project not to try and replicate the original magnesium structures or to try and reproduce them in aluminium due to fears of material failure and chassis cracking, as experienced on the race cars.

Stradale “Production” Bodywork

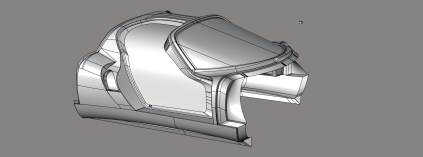

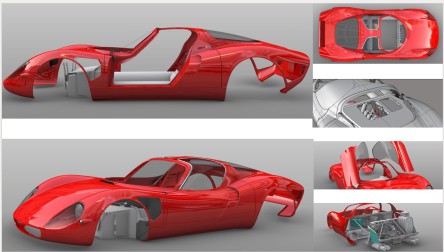

The Production version of the Stradale features a number of changes to make the car easier to live with and make road legal.

These included a higher roof line and ride height, larger door openings, wing mirrors and side repeaters.

They also incorporated wind down windows rather than sliders, other changes include an air vent for cabin ventilation, space for a spare wheel and radiator cooling ducts,

The Production version has 2 headlights which were mounted higher and the front indicators repositioned for legal compliance.

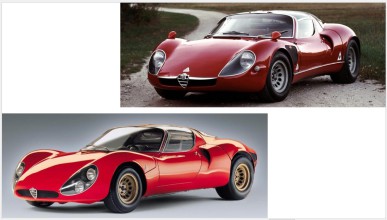

Production version above versus Prototipo below.

Following feedback from customers we decided to develop a set of “Production” bodywork to compliment the rolling chassis we already produced. This would incorporate aluminium front and rear clams and outer door skins.

We therefore decided to base our car on the "Production" version of the car, but with the provision to allow customers to choose a 4 or 2 headlight front end.

Design work included the door inner skins and hinge mechanism, plus fitment of the bodywork to the chassis.

It was also used to create the inner bulkhead panels for the centre tub, to allow fitment of a modern HVAC unit and collapsible steering column.

A lot of time was also spent modelling the engine and gearbox position to allow room for ancillaries such as dry sump tank, header tank, exhausts etc.

We work with a local company to produce the aluminium front and rear clams. Customers had already had "Prototipo" aluminium bodywork produced using the eisting GRP panels as patterns. This meant that any inaccuracies in the GRP bodywork (which are up to 30mm from one side to the other ) were carried over, and that customers first needed to buy a set of the GRP bodywork.

For the "Production" aluminium bodywork we started from scratch to ensure accurcay and to allow us to incorporate the "Production features.

We initially looked at creating an "egg box" pattern using CNC plywood formers, but decided it would be more accurate to create composite patterns for the panel beaters to form the aluminium panels over.

The front clam pattern is split just in front of the wheel arch to allow either 2 headlight or 4 headlight bodywork to be produced based on customer preferences.

ENGINES

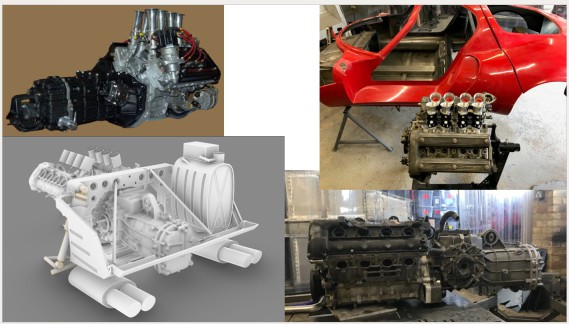

The engine bay on the Stradale follows the shape of the original, which limits the range of engines that can be fitted. It will however accept the Alfa Romeo Montreal V8 engine or the Maserati V8 engine used in the Alfa Romeo 8C.

The Montreal engine is similar to the original engine, but is some 60mm longer and has engine mounts in a different position. The engine will not fit the chassis with the original Spica mechanical fuel injection system, so we have developed a throttle body kit and upgrades to allow the engines to be run with a modern engine control unit with full control of fuel and ignition.

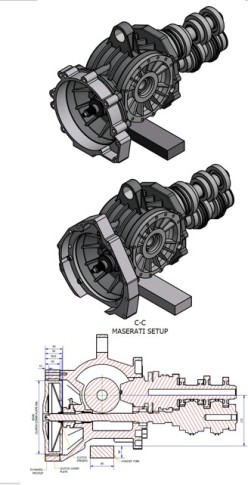

The Maserati 4.2l V8 F136 engine is closely related to the Alfa Romeo 8C V8 engine, and is available with a dry sump as standard. There are used engines available at good prices and we have developed a throttle body kit with 8 vertical throttle trumpets and a standalone ECU to allow the engines to be used in the Stradale. Scans of the engine were used to develop designs for the engine ancillaries.

GEARBOXES

We have developed our own gearbox based on using Porsche 911 (997) internals in a new front casing designed to fit the Stradale layout.

It utilises a separate short bellhousing to allow the gearbox to be used with either the Montreal or Maserati engines. We have also developed a flywheel and clutch package for the two engines with a single plate clutch for the Montreal and twin plate clutch for the Maserati engine.

The Stradale is a small car and there are limited gearboxes that will fit, it needs to be small and have the output flanges above the input shaft, with a gearbox mount above the output flanges.

Other gearbox choices include the original Colotti 6 speed transaxle but this is expensive and only available with straight cut gears and dog gear engagement, so not ideal for road use.

For customers choosing the Maserati engine the Ferrari 430 gearbox will bolt directly on and is a good option. It can be made to fit by cutting away parts of the gearbox to clear the Stradale chassis tube. However these gearboxes are getting scarce and need to be the manual gearchange version, rather than the F1 paddle shift.

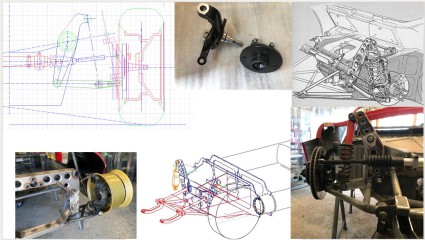

Numerous photos were used to fill in the design of the suspension, with the added complication that the Stradale cars are different to the Tipo 33 race cars.

All parts were drawn in CAD and tolerances and material specifications confirmed.

From this jigs were laser cut to allow parts to be made repeatably with high accuracy.

Where possible modern parts were used to improve on the original design, in the rear upright shown on this page a modern wheel bearing and hub is used to replace the old taper bearings used on the 1960’s cars.

The front suspension was also reported to have poor rigidity of the upper wishbone, so a welded assembly replaces the original bolted design.

The image also shows the Original Stradale front suspension versus our version which uses all new components.

Front uprights were sourced to suit the original geometry, but required modifying to work with the bespoke hubs and larger bearings.

A range of dampers are available depending upon budget and car’s set up for road or track use.

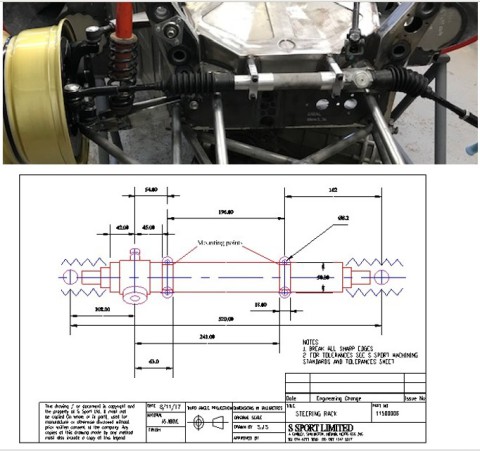

STEERING AND BRAKES

We offer a variety of brake options, depending upon wheel size. Original cars had 13” wheels which limits brake disc size to 260mm on the front axle.

Customers using the Maserati engine are encouraged to use 15” wheels which allows the use of 320mm front discs.

Both options use two piece ventilated discs with aluminium bells and 4 pot calipers front and rear.

Rear brakes can be inboard or outboard depending upon choice of gearbox, both incorporate a handbrake mechanism.

WHEELS AND TYRES

We can supply either 13” or 15” wheels for the Stradale.

The 13” wheels are replicas of the original but while the original Dunlop CR65 tyres are still available they are no longer legal for road use in many countries.

For this reason we have developed 15” versions of the wheels which can be used with road legal Pirelli P7 tyres.

Both wheel sizes use the same wheel offsets to give the correct period feel of the original Stradale cars.

INTERIOR

Although only a few Stradale’s were built, there is a wide variety of interior designs. We have decided to use the "Prototipo" interior to which we feel is a better design than used on the "Production" cars.

We have recreated the dash with a large tacho behind the wheel, which unlike the "Prototipo" car also incorporates a speedo and odemeter to ssatisfy IVA requirements plus 5 auxiliary gauges in a central cluster

One of the main differences is the decision to use column mounted switch gear for the lights and indicators.

We have recreated the original gauge faces as shown below.